Our dry ice production line integrates a dry ice pellet machine, a pellet briquetting machine and a packaging machine for the production of dry ice pellets and dry ice blocks, providing you with a full range of cleaning solutions. Not only that, we also provide you with reliable quality bags for easy storage and use. This complete line is worth investing in for large scaled production.

Video on how to produce dry ice pellets & blocks

Why invest in the dry ice production line for pellets, blocks & packages?

As an investor, you definitely want to make a valuable investment, and so does your investment in a dry ice pellet briquette production line, so read on to see what our production line can bring for you:

- Market Demand: Dry ice pellets and dry ice blocks have a wide range of applications in various industries, such as cleaning, defrosting, stage effects, etc. Investing in Shuliy dry ice production line machines can meet the market demand for dry ice products and create stable sales opportunities for you.

- High return: With high production capacity and high efficiency, the dry ice production line can quickly produce large quantities of dry ice pellets and dry ice bricks, resulting in significant sales revenue and return on investment.

- Flexible application: The dry ice pellet briquetting line can produce different sizes and thicknesses of dry ice pellets and briquettes to meet the requirements of different applications in various industries and provide customized solutions.

- Additional service sales: In addition to the dry ice product itself, you can provide related additional services such as dry ice packaging, distribution and storage equipment to increase added value and revenue streams.

In summary, investing in a dry ice pellet briquetting line can generate steady profits and business growth for you while meeting the market demand for dry ice products. As an investment with potential and promise, dry ice production equipment will provide you with the opportunity for success and sustainability.

Working process of the dry ice production line for pelleting, briquetting & package

Step 1: dry ice maker for pellets

It uses advanced technology to convert liquid carbon dioxide into dry ice pellets. The dry ice production machine has efficient and precise pelletizing capability, and the size and thickness of the pellets can be adjusted according to demand. These dry ice pellets have excellent cleaning ability and low-temperature characteristics and can be used in a wide range of cleaning tasks in various industries. It is also important to note that because the dry ice production line is commercial and large, it uses a dry ice pellet machine with two outlets.

Step 2: dry ice production machine to press dry ice pellets into dry ice blocks

It compresses dry ice pellets into solid dry ice blocks with high pressure. The pellet briquetter can adjust the pressure and the size of the dry ice block as needed to suit the requirements of different application scenarios. Dry ice blocks have a longer duration and lower evaporation rate, making them easier and more economical to transport, store and clean.

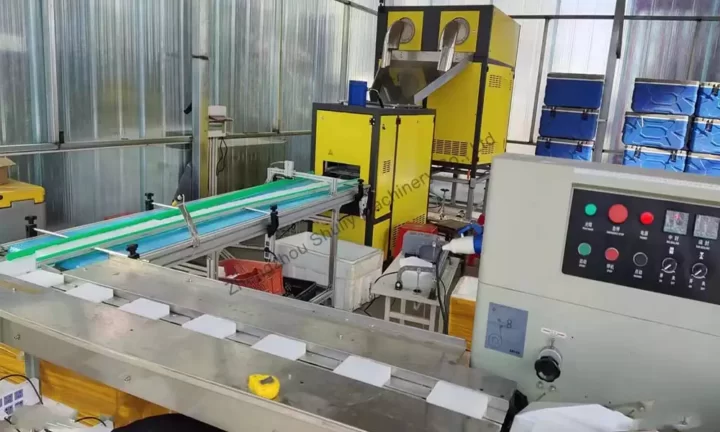

Step 3: dry ice package machine

For your convenience and storage, we pack dry ice cubes in the final step using a packaging machine. And we will also provide high-quality bags. The quality of dry ice blocks packed in bags is guaranteed because these bags have excellent sealing properties that prevent the evaporation of dry ice and the entry of external impurities.

Strengths of industrial dry ice production line for sale

- Flexibility: The dry ice production line can produce a wide range of sizes of dry ice pellets and blocks to meet the needs of different customers.

- Automation: The line for dry ice production is highly automated, reducing manual operations and error rates, and improving production efficiency and quality.

- Environmentally friendly: The production process does not produce any pollutants and dry ice itself is an environmentally friendly cleaning agent.

- Cost saving: By making a one-time investment to build the dry ice production line, the production cost can be significantly reduced and the competitiveness of the products can be improved.

- Customization: It can provide personalized customization service according to customers’ needs to meet different production requirements.

- Versatility: The dry ice production line can not only produce dry ice pellets and blocks, but also cooperate with pillow packing machine to realize packaging and transportation of dry ice products.

How about the dry ice production line price?

The price of a dry ice production line varies depending on factors such as equipment model, size, configuration and brand. Generally, the price of the whole production line varies, and this price includes not only the cost of the equipment itself, but also the related service, transportation, installation and commissioning costs. In addition, each customer’s needs are different, so customization requirements will also affect the price.

If you need to know the exact price, please contact us now and our professional sales manager will offer you the most suitable solution and price quote.

Call me now for your dry ice business!

Investing in the dry ice production line for pellets & blocks not only can meet the market demand, but also can get considerable profit return. Shuliy dry ice pellet & block production line has efficient and stable production capacity, perfect after-sales service and quality assurance to escort your investment. Contact us now to customize your own dry ice production line, and let’s create a better future together!