With the growing demand for cold chain logistics, dry ice is increasingly used in industries such as food transportation, biopharmaceuticals, and online fresh produce delivery. Many customers wish to produce dry ice pellets themselves but don’t know where to start. This article will provide a clear process from raw materials to finished product using Shuliy dry ice pellet machine.

Advantages of dry ice pellets in cold chain applications

Dry ice sublimates directly into carbon dioxide without liquefying, reaching temperatures as low as -78.5°C (-123.6°F) and delivering exceptional cooling capacity. Compared to traditional ice packs or ice blocks, dry ice pellets offer the following benefits:

- Lower temperatures and longer duration

- No water production, keeping packaging dry

- Small particles ideal for filling various insulated containers

- Suitable for food, pharmaceuticals, fresh produce, e-commerce logistics, and more

For these reasons, an increasing number of companies are choosing to establish their own dry ice pellet production lines.

Essential equipment for dry ice pellet production: Shuliy dry ice pelletizer

Shuliy Dry Ice Pellet Machine is a specialized device that rapidly converts liquid carbon dioxide into solid pellets, featuring the following characteristics:

- Single-step molding with uniform pellet size

- High-efficiency automatic compression and pelletization

- Suitable for multiple pellet specifications (3mm, 16mm, etc.)

- Stainless steel construction with food-grade design ensures enhanced safety and hygiene

- Robust continuous production capacity suitable for industrial and commercial manufacturing

For those new to the dry ice industry, utilizing a dry ice pelletizer enables rapid establishment of a stable production line.

Dry ice pellet production process (From liquid CO₂ to finished product)

- Prepare liquid carbon dioxide (LCO₂)

- This serves as the base material for dry ice production and must be stored in gas cylinders at a pressure of 1.8–2.2 MPa.

- Start the dry ice pellet machine and establish a pressure differential

- Upon machine startup, a pressure differential is automatically generated to draw liquid CO₂ into the unit.

- Liquid CO₂ injection and pressure reduction solidification

- Upon entering the mold cavity:

- Instantaneous pressure reduction forms snow-like solid CO₂

- Hydraulic systems compress it into high-density dry ice blocks

- Upon entering the mold cavity:

- Extrusion molding into pellets

- Shuliy pelletizing molds compress the pressed dry ice into 3–16mm pellets, with specifications adjustable per customer requirements.

- Dry ice pellet collection and cold chain deployment

- Finished pellets are bagged, stored, or directly integrated into transportation chains.

Main applications of dry ice pellets

- Fresh food cold chain transportation

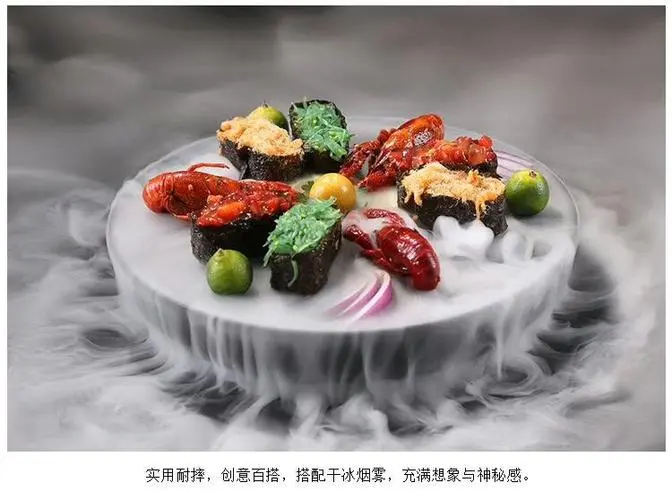

- Examples: Seafood, beef/mutton, fruits, dairy products, etc.

- Biopharmaceutical logistics

- Temperature-controlled transportation for vaccines, plasma, laboratory samples, etc.

- Food industry & catering distribution

- Preservation for baked goods, takeout, and frozen foods.

- Industrial cleaning & blasting

- Dry ice pellets power dry ice blasting machines for industrial equipment surface cleaning.

Shuliy dry ice pellet machines are widely adopted by cold chain enterprises, food factories, pharmaceutical companies, and dry ice processors.

How to select the right dry ice pellet maker?

When choosing equipment, consider the following aspects:

- Does the daily output capacity meet your requirements?

- Are pellet specifications adjustable?

- Does it support continuous production?

- Does it comply with food-grade hygiene standards?

- Is after-sales service comprehensive?

Shuliy offers multiple equipment types ranging from 5kg/h to over 200kg/h, with customizable molds and export voltages based on client needs.

Contact us now!

To achieve stable dry ice pellet production for cold chain transportation, selecting a high-efficiency, professional dry ice pelletizer is crucial. Shuliy dry ice pelletizers have become the preferred choice for cold chain enterprises due to their high automation, uniform pelletization, and stable performance.

If you plan to launch a dry ice processing business, please contact us for technical solutions and quotation support.